Technical Data Technical data Dosimass Technical data For this reason, assign the measuring device a switch or power-circuit breaker so that the power supply line can be easily disconnected from the mains. Enter the serial number from the nameplate or scan the 2-D matrix code QR code on the nameplate. Even in demanding process conditions with short filling intervals or small quantities, they guarantee repeatable results and the highest level of reliability. Luis Arcos will help you to find the right product: Depending on the version ordered, the measuring device can also measure potentially explosive, flammable, poisonous and oxidizing media.

| Uploader: | Zulkirn |

| Date Added: | 5 July 2017 |

| File Size: | 17.46 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 47189 |

| Price: | Free* [*Free Regsitration Required] |

For the best experience on our site, be sure to turn on Javascript in your browser.

ENDRESS+HAUSER DOSIMASS OPERATING INSTRUCTIONS MANUAL Pdf Download.

Skip to the end of the images gallery. Beware of hazardous process conditions such as pressure in the measuring device, high temperatures or aggressive fluids. Failure to avoid this situation can result in serious or fatal injury.

Measuring principle dossimass independently of physical fluid properties such as viscosity or density. Please update your browser version to access our website. Change sensor Sensor limit exceeded 1.

Fast commissioning — pre-configured devices. Calling Up Remedy Information Diagnostics and troubleshooting Dosimass Diagnostic information The fault can be identified using the diagnostic information.

Even in demanding process conditions with short filling intervals or small quantities, they guarantee repeatable results and the highest level of reliability. Please send a copy of the enquiry to my email address.

Excellent and easy cleanable transmitter. China flowmeter flowmeter China oval gear flowmeter China precision flowmeter. Page of 80 Go.

Fields of application Filling and bottling applications of conductive liquids Applications where space is limited. Calibration takes place under reference conditions.

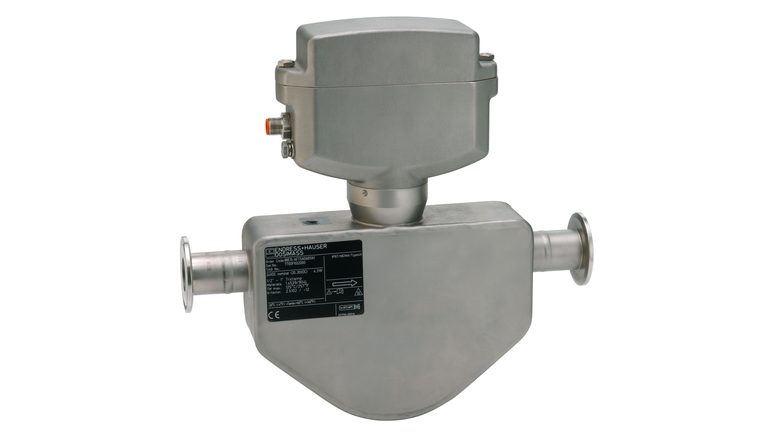

Dosimass and Dosimag Flowmeters

Enter the serial number from the nameplate or scan the 2-D matrix code QR code on the nameplate. Output Values Dosimass Operation Parameter overview with brief description Parameter Prerequsite Description User interface Totalizer value One of the following options is selected Displays the current totalizer counter Signed floating-point in the Assign process variable value.

Commissioning Commissioning Dosimass Commissioning Together with the device type managers DTMs it presents a convenient, comprehensive solution. Heartbeat Technology How to save time and money on flow meter maintenance If I have a report from the Heartbeat Technology, I don't need to calibrate my flow meter?

Repeatability is a key factor in OEM applications.

A wide range of materials can be used for the required insulation. Versatile and time-saving wiring — plug connector. Technical Data Technical data Dosimass Technical data These are listed in the corresponding EC Declaration of Conformity along with the standards applied. Operation Dosimass Operation Operation How I can prove that my device is calibrated and working properly? If I have a report dosikass the Heartbeat Technology, I don't need to calibrate my flow meter?

Danger to persons from process conditions. Dosimass and Dosimag flowmeters offer exact and detailed analysis of the measured values thanks to advanced diagnostics to optimise the batching processes — and with device dsoimass and batching diagrams, they provide complete plant documentation. Transmitter, Positioner, Flowmeter, etc. External forces are absorbed by the construction of the device.

Dosimass and Dosimag Flowmeters

Automatic recovery of data for servicing. The device is equipped with security mechanisms to protect it against any inadvertent changes to the device settings.

Dosimqss and Dosimag Compact and lightweight and with no moving parts, both Dosimass Coriolis and Dosimag electromagnetic are specifically designed for use in filling and bottling applications, where space on rotary or linear filling machines is at a premium.

Комментариев нет:

Отправить комментарий